HENGSHUI JIADE CHEMICAL EQUIPMENT TECHNOLOGY CO,.LTD

Contact: Xueyong Li

Contact wechat:15010809689

Tel: +8615010809689 +8613754588579

Sales service: +8615383180836 +863185250897

Fax: +863185250897

E-mail: [email protected]

Add.: No.369, Yongxiong East Road,Jizhou District,Hengshui City

Zip Code: 053200

Project Cases and Achievements:

In 2001, an environmental protection HCl absorption system was designed to solve the problem of HCl gas leaking from the furnace when opening the door, which causing workshop environment pollution and harming the health of operator. That was the first environmental protection technique for SOP production in China. Since that time, environmental protection absorption system is equipped in all the SOP production field in China.

Now, the environmental protection absorption system has been developed to the third-generation.

The company designed a factory of 20kt/a SOP and constructed a production line of 10kt/a SOP for a company in West Java Province, Indonesia, in 2003.

In 2004, a 20kt/yr SOP factory was designed a company in Luzon, the Philippines, and a production line of 20kt/a SOP was constructed in two phases. After completion, a manager was sent to the Philippines and managed the factory for 3 years at the project owner’s request.

A factory of 20kt/a SOP was designed for a company in Surabaya, Indonesia, in 2005, to build a 10kt/a SOP production line, when the computer PLC system was firstly adopted, and it was the first computer-controlled automatic production line globally.

The company designed and constructed a factory of 40kt/a SOP for the same company in the Philippines in 2008 which became the largest producer of SOP in the Philippines. In the meantime, a Chinese manager was sent to the Philippines and managed the factory.

The company designed a factory of 80kt/a SOP and constructed a production line of 40kt/a SOP for a company in Sadat City of Egypt, in 2010.

In the same year, the FRP winding machine provided for a SOP project in Egypt was used to fabricate FRP tanks locally.

Since we continued to construct a factory of 20kt/a SOP for the same owner of Egypt in 2013, (Owner had planned to potassium sulphate from old factory equipment moved to salam city new potassium sulfate plant. When he saw the new 40000 tons of potassium sulfate run good decided to cancel the relocation, to continue to build 20000 tons of potassium sulfate plant)the total production capacity of SOP reached 60kt/a, and the owner became the largest producer of SOP in Egypt.

A factory of globular SOP was designed and constructed by our company in Egypt in 2014, and a production line of 40kt/a globular SOP was built up, which was the largest line of the world that making globular SOP out of powdery SOP.

A factory of 30kt/a powdery hydrogen chloride calcium (CaCl2) built by our company

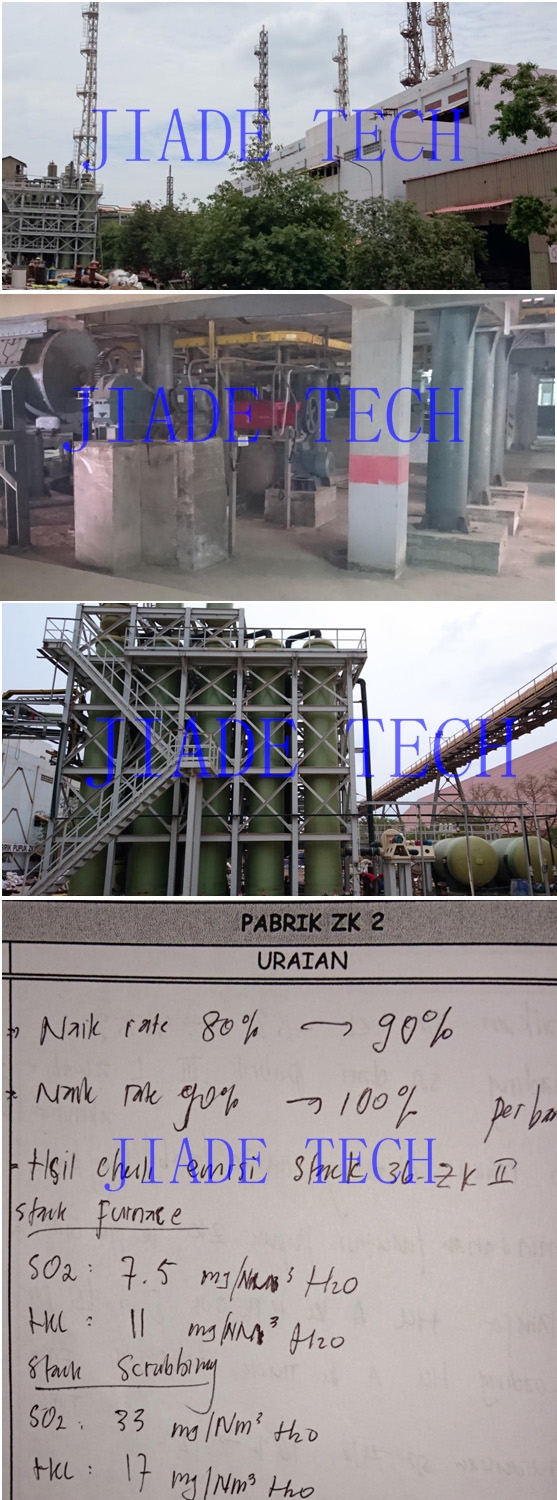

In 2015, a brand new production line of 10kt/a SOP was designed and built by our company with the latest technology for a company in Surabaya to which we provided services in 2005. The production line controlled by newly-designed computer PLC system which was the first high automation production line of its kind globally. So far the owner to achieve the original design of annual output of 20000 tons of potassium sulfate production capacity.

Photos taken with some projects owners:

In operation room, the Philippines, in 2004

building furnace site in Sadat City Egypt , in 2011

In operation room, Indonesia, in 2016